In the modern era of Industry 4.0, the integration of IOT (Internet of Things) with PLCs (Programmable Logic Controllers) and C# programming has become a groundbreaking trend in industrial automation. This fusion enables seamless communication between industrial machines and cloud platforms, paving the way for smarter, more efficient systems. In this blog, we’ll explore what makes this integration so powerful, its applications, and a high-level guide on how to implement it.

What is IoT Integration with PLCs and C#?

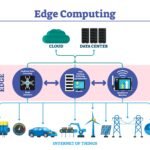

IoT integration with PLCs involves connecting industrial controllers to the internet, allowing them to send and receive data in real time. C# acts as the middleware that bridges the gap between PLCs and IoT platforms such as Azure IoT Hub, AWS IoT, or Google Cloud IoT. Here’s how each component fits into the system:

- PLCs: Handle the real-time control of machinery and collect data from sensors.

- IoT: Provides the infrastructure to store, process, and analyze data remotely.

- C#: Acts as the software layer to process data, manage communication protocols, and enable visualization or further analysis.

Why is IoT Integration Important in Industrial Automation?

Here are some key reasons why IoT integration with PLCs is crucial for modern industries:

- Real-Time Monitoring: IoT provides real-time access to machine data, improving operational transparency.

- Predictive Maintenance: By analyzing data trends, you can predict equipment failures before they happen.

- Remote Control: Operators can control and monitor equipment from anywhere in the world.

- Data-Driven Decisions: IoT enables advanced analytics, helping businesses optimize processes and reduce costs.

- Scalability: Easily scale systems to accommodate more devices and greater complexity.

Unlocking the Future: IoT Integration with PLCs in Industrial Automation

In today’s fast-paced industrial landscape, the integration of Internet of Things (IoT) technology with Programmable Logic Controllers (PLCs) is transforming how businesses operate. This combination not only enhances efficiency and productivity but also paves the way for innovative solutions that can significantly impact the manufacturing sector. In this blog, we’ll explore the concepts of IoT and PLCs, their benefits, applications, and the future of industrial automation.

Understanding IoT and PLCs

What is IoT?The Internet of Things refers to the network of physical devices embedded with sensors, software, and other technologies to connect and exchange data with other devices and systems over the Internet. In industrial settings, IoT enables machines to communicate, gather data, and make autonomous decisions, leading to smarter operations.What are PLCs?Programmable Logic Controllers are industrial digital computers used for automation of manufacturing processes, such as control of machinery on factory assembly lines, amusement rides, or lighting fixtures. PLCs execute a series of commands based on input from various sensors and devices, making them essential for process control and monitoring.

The Importance of Integrating IoT with PLCs

- Real-Time Data Monitoring: Integrating IoT with PLCs allows for real-time monitoring of machinery and processes. This means that operators can receive instant data on performance, enabling swift decision-making and immediate action when issues arise.

- Predictive Maintenance: One of the most significant benefits of IoT integration is predictive maintenance. By continuously monitoring equipment and analyzing data trends, companies can predict failures before they occur. This not only minimizes downtime but also reduces maintenance costs.

- Enhanced Efficiency: IoT-enabled PLCs can optimize processes by analyzing data and providing insights that lead to improved operational efficiency. This can include optimizing production schedules, reducing energy consumption, and minimizing waste.

- Remote Access and Control: With IoT, operators can access and control PLCs remotely from anywhere in the world. This flexibility is especially beneficial for companies with multiple facilities, allowing for centralized monitoring and management.

- Scalability: As businesses grow, integrating IoT with PLCs allows for easy scalability. New devices and sensors can be added to the network without significant overhauls to the existing infrastructure.

Applications of IoT Integration in Industries

The applications of IoT and PLC integration are vast and varied across different industries:

- Manufacturing: Smart factories utilize IoT sensors connected to PLCs to monitor production lines, manage inventory, and streamline operations.

- Energy Management: IoT devices can monitor energy usage in real-time, allowing for better energy management and cost savings in industrial plants.

- Agriculture: Smart farming utilizes IoT sensors connected to PLCs to automate irrigation systems, monitor soil conditions, and optimize crop production.

- Transportation: IoT-enabled PLCs are used in logistics to track vehicle locations, monitor fuel consumption, and manage fleet operations effectively.

- Smart Cities: IoT integration can help manage infrastructure, such as traffic lights and public transportation systems, leading to improved urban living conditions.

Challenges and Considerations

While the benefits of IoT integration with PLCs are substantial, there are challenges to consider:

- Data Security: With the increased connectivity comes the risk of cyber threats. It’s crucial to implement robust security measures to protect sensitive data.

- Interoperability: Different manufacturers may have varying standards for PLCs and IoT devices, making integration challenging. Choosing compatible technologies and protocols is essential.

- Initial Investment: The transition to IoT-enabled systems may require significant upfront investment in technology and training.

The Future of Industrial Automation

The future of industrial automation is bright, with IoT integration at the forefront. Advancements in technologies such as 5G, edge computing, and artificial intelligence (AI) will further enhance the capabilities of IoT and PLCs. As industries become more interconnected, the potential for innovation and efficiency will continue to grow.As a digital marketer and tech enthusiast, embracing these changes can provide new opportunities for businesses and individuals alike. By understanding and leveraging IoT integration, you can position yourself at the cutting edge of industrial automation.

Conclusion

Integrating IoT with PLCs is not just a trend; it is a significant shift in how industries approach automation and efficiency. The benefits of real-time monitoring, predictive maintenance, and enhanced control are invaluable in today’s competitive landscape. As we move forward, those who adapt to these technological advancements will thrive in the evolving industrial ecosystem. If you wish to explore more about IoT, PLCs, or any related topics, feel free to reach out! Let’s embrace the future of industrial automation together!

Leave a Reply