The Role of AI and Machine Learning in Industrial Automation

Why AI & Machine Learning Matter in Industrial Automation

Core AI/Machine Learning Technologies in Automation

Predictive Maintenance: Avoiding Downtime Before It Happens

Process Optimization: Smarter, Faster, Better

Quality Control & Defect Detection Powered by AI

Energy Management with Machine Learning

AI‑Driven Robotics, Autonomous Systems & Cobots

Industry 4.0 Use Cases Across Sectors

Challenges, Risks & Ethical Considerations

Implementing AI in Your Factory: Roadmap & Best Practices

Future Outlook: What’s Next in AI Industrial Automation

Artificial intelligence (AI) and machine learning (ML) are rapidly redefining how factories operate—from scheduling upkeep to making real‑time adjustments on the assembly line. In the age of Industry 4.0, they’re no longer experimental add‑ons — they’re essential. In this post, we explore how AI and ML are enhancing predictive maintenance, process optimization, quality assurance, energy efficiency, and autonomous robotics across industries. We’ll also dive into implementation strategies, challenges, and what comes next.

1. Why AI & Machine Learning Matter in Industrial Automation

- Define Industrial 4.0 context

- Compare traditional automation vs AI‑powered systems

- Key benefits: responsiveness, reduced downtime, customization

- Facts & small stats (hypothetical but plausible): “By 2028, AI in manufacturing predicted to grow +40%.”

2. Core AI/Machine Learning Technologies in Automation

- Machine vision & deep learning

- Time‑series analytics

- Reinforcement learning

- Explainable AI for transparency

- Sensors + IoT data pipelines

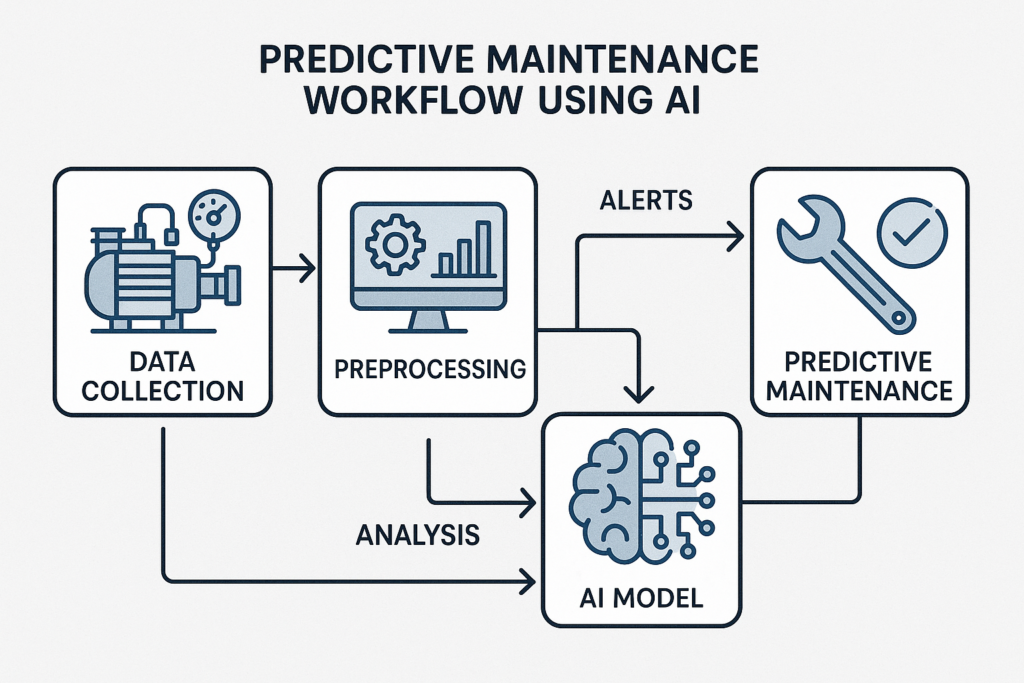

3. Predictive Maintenance

- Traditional calendar‑based vs AI‑based maintenance

- Vibration, temperature, lubricant monitoring

- Anomaly detection models; digital twins

- Outcomes: 20–30% uptime improvement, 15% cost cut

4. Process Optimization

- Real‑time data + digital twins

- AI‑tuned parameters: temperature, flow, speed

- Adaptive batch production

- Example: chemical reactor optimizing yield

5. Quality Control & Defect Detection

- Computer vision inspecting welds, paint, surface

- Reinforcement learning improving tolerances

- Cases: semiconductor fabs, automotive painting lines

6. Energy Management

- Smart HVAC/lighting via ML demand forecasting

- Optimizing compressed air, steam systems

- Energy intensity reduction by 10–20%

7. AI‑Driven Robotics & Autonomous Systems

- Collaborative robots (cobots) learning from humans

- Automated guided vehicles (AGVs) with RL routes

- Safety, adaptability, reduced cycle time

8. Industry 4.0 Use Cases

- Automotive (assembly, quality, scheduling)

- Oil & Gas (pipeline health, drilling efficiency)

- Food & Beverage (sanitation standards)

- Pharmaceuticals (compliance, traceability)

9. Challenges & Ethics

- Data quality, integration with legacy systems

- Need for skilled workforce, retraining “AI won’t replace humans—humans with AI will.”

- Transparency, bias, cybersecurity

- ROI hurdles & change management

10. Implementation Roadmap

- Identify use cases

- Pilot with limited scope

- Build cross‑functional team

- Scale gradually

- Monitor ROI & performance

- Continuous improvement

11. Future Outlook

- AI + 5G, edge computing synergy

- Generative design, zero‑defect manufacturing

- Human‑AI collaboration

- Sustainability & carbon tracking

Conclusion

Recap benefits—reduced downtime, better quality, efficiency gains. Highlight gradual adoption strategy. Final CTA:

- Encourage readers: “Start assessing your factories today—download our free [Industrial AI Readiness Checklist]!”

- Internal link placeholder.

Leave a Reply