<a id=”intro”></a>

1. Introduction: The Fourth Industrial Revolution on Wheels

The automotive industry stands at the forefront of the Fourth Industrial Revolution, powered by smart manufacturing—a fusion of Internet of Things (IoT), sensor technology, and real-time analytics. These innovations are reshaping production lines, slashing costs, elevating quality, and boosting sustainability.

Historically, manufacturing ran on rigid, linear processes. Today’s demands—customization, zero defects, digital traceability—have forced automotive giants and suppliers to embrace a data-driven, interconnected ecosystem. The result? A leaner, more responsive, more efficient manufacturing paradigm.

<a id=”pillars”></a>

2. Core Pillars of Smart Manufacturing in the Auto Sector

2.1 IoT and Connected Machinery

- Industrial IoT gateways link machinery—presses, robots—to networks, enabling centralized monitoring and remote command.

- Digital twins simulate physical assets virtually, enabling predictive maintenance, faster troubleshooting, and process optimization.

- Asset tracking via RFID or BLE ensures tools, components, and vehicles are located, monitored, and guided seamlessly through the line.

2.2 Advanced Sensors & Condition Monitoring

- Vibration & acoustic sensors detect anomalies, like bearing wear, before failure.

- Thermal and infrared imaging spots hotspots—overheating robotic arms, misaligned welds, or poorly cured materials.

- Pressure, flow, force sensors optimize pneumatic and hydraulic systems, reducing waste and boosting precision.

2.3 Real‑Time Data Analytics & Machine Learning

- Edge analytics process data locally for instant alerts—latency is minimized, uptime maximized.

- Predictive maintenance algorithms forecast machine breakdowns using anomaly detection.

- Computer-vision on the line inspects weld seams, paint gloss, and surface defects with high speed and accuracy.

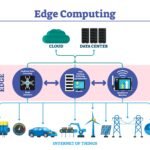

2.4 Cloud, Edge, and 5G Infrastructure

- 5G wireless networks enable ultra-fast, low-latency connectivity for mobile robots and AR-enabled workers.

- Hybrid edge-cloud ecosystems store anonymized data centrally for trend analysis while edge devices handle mission-critical processing.

- Cyber-physical resilience: secure protocols (TLS, OPC-UA) and network segmentation protect operational tech (OT) from vulnerabilities.

<a id=”benefits”></a>

3. Key Benefits Driving Adoption

💡 Production Efficiency & OEE Gains

Smart systems boost Overall Equipment Effectiveness by reducing unplanned downtime and improving line speeds.

✅ Quality Assurance & Defect Reduction

AI vision systems and sensor feedback enable zero-defect strategies—vital in welding, painting, component assembly.

💰 Cost Optimization

- Predictive maintenance slashes repair costs by up to 30%.

- Energy management orchestrates consumption based on demand, peak load, or off-shift rates.

🌱 Sustainability & Resource Efficiency

Smart automation streamlines material usage, slashes emissions, and ensures environmental compliance—crucial under evolving global directives.

🔄 Flexible Production & Mass Customization

Digital control enables rapid switches between models, making it feasible to serve niche markets or limited-edition runs profitably.

<a id=”technologies”></a>

4. Enabling Technologies & Integration

| Technology | Role in Smart Manufacturing |

|---|---|

| OPC-UA, MQTT | Standard OT/IT protocols enabling secure, real-time communication |

| Digital Twins | Enable modeling of system behavior for “what-if” scenarios and failure analysis |

| 5G / Private LTE | Wireless backbone for reliable, low-latency data transfer |

| AI/ML frameworks | Analyze patterns across sensor streams for predictive insights and anomaly detection |

| Cloud/data lakes | Aggregate historical data across plants for deeper insights and cross-site comparisons |

| Cybersecurity tools | Secure data transmission, threat detection, and OT-IT isolation |

| AR/VR overlays | Support maintenance, assembly guidance, and worker training in context |

Key integration steps include:

- Data ingestion from OT to IT (via OPC-UA/MQTT)

- Local analytics via edge devices (NVIDIA Jetson, Intel OpenVINO)

- Dashboarding and reporting in cloud platforms (Azure Digital Twins, AWS IoT Analytics)

- IT-OT alignment and stakeholder training

<a id=”usecases”></a>

5. Industry Use Cases & Success Stories

5.1 Mercedes-Benz Sindelfingen

Deployed 5G-powered AGVs and condition monitoring, reducing unplanned downtime by ~40%.

5.2 Ford Cologne Assembly Plant

Trialed MCU-managed production lines with NVIDIA Jetson, cutting cycle time by ~20%.

5.3 BMW Leipzig Plant

Uses AI vision systems for seam inspection—able to detect defects <0.3 mm in real time.

5.4 Magna International Supplier

Installed vibration sensors on stamping presses—predictive alerts reduced unscheduled stops by ~25%.

<a id=”challenges”></a>

6. Challenges & Risk Management

📊 Data Quality & Integration

OT data is often siloed. Effective transformation, mapping, and synchronization are essential.

🛡️ Cyber Security

Smart OEM networks must be segmented with firewalls, tokenized access, and routine penetration testing.

👥 Workforce & Cultural Adoption

Upskilling workers in data and systems is mission-critical. Organizational buy‑in is key.

💸 Initial Investment

CapEx for sensors, gateways, networks is considerable. ROI hinges on strategic deployment and thorough cost‑benefit analysis.

⚖️ Regulatory Compliance

Data privacy (GDPR), emissions laws, labor regulations—all must be considered in data capture and analytics.

<a id=”roadmap”></a>

7. Roadmap to Implementation: A Step‑by‑Step Guide

- Pilot Lines: Choose bottleneck or high-value areas for initial rollout.

- Assess Data Flow: Understand where sensor data resides and how to capture it.

- Install Sensors & Gateways: Start lean; focus on vibration, temperature, or quality sensors.

- Deploy Edge Analytics: Enable closed-loop alerts for anomaly detection.

- Integration with Cloud Dashboards: Visualize KPIs—OEE, energy, defect rates.

- Scale Gradually: Add equipment, lines, sites phased by ROI analysis.

- Train Teams & Iterate: Use feedback loops to refine processes and systems.

- Embed Cybersecurity: Review architecture, test for vulnerabilities, and train teams.

- Measure Impact: Track OEE lift, downtime reduction, cost savings, quality metrics.

- Continuous Optimization: Refine with A/B testing, process simulation.

<a id=”future”></a>

8. Future Trends & Industry Outlook

- AI-Designed Production: Systems will self-optimize via reinforced learning.

- Blockchain Traceability: Full provenance from raw materials to finished vehicles.

- Ultra-Low Latency 6G: Real-time autonomous decision-making begins on the line.

- Human–Robot Collaboration: Smart cobots work side-by-side, using AR to guide workers.

- Sustainability by Design: Smart factories offset emissions and dynamically source renewable energy.

<a id=”conclusion”></a>

9. Conclusion & Strategic Takeaways

Smart manufacturing in automotive is no longer optional—it’s a business imperative. From IoT-connected machinery to real-time analytics, firms that embrace digital transformation gain:

- Higher productivity & uptime

- Better quality with fewer defects

- Lower costs & energy consumption

- Flexibility for customization

- Stronger compliance and sustainability

The real winners will be those who marry technology adoption with change management, robust cybersecurity, and a data-driven culture.

10. FAQs about Smart Manufacturing in Automotive

Q1: How much can predictive maintenance reduce downtime?

Through data-driven condition monitoring and AI, manufacturers typically see 20–40% reduction in unplanned downtime.

Q2: Are legacy machines usable in a smart factory?

Yes—existing equipment can be retrofitted with IoT sensors and gateways, then integrated via OT‑IT protocols like OPC‑UA and MQTT.

Q3: Is 5G essential for smart manufacturing?

Not essential, but critical for wireless, low-latency use cases (AGVs, AR, collaborative robots). Wi‑Fi 6 and private LTE are alternatives.

Q4: Which KPIs improve most?

Key metrics: OEE, mean time between failure (MTBF), cycle time, energy per part, defects per million (DPM).

Q5: How to justify smart manufacturing investments?

Build a business case using projected reductions in downtime, scrap, energy costs, plus ROI metrics (IRR, payback period).

Leave a Reply