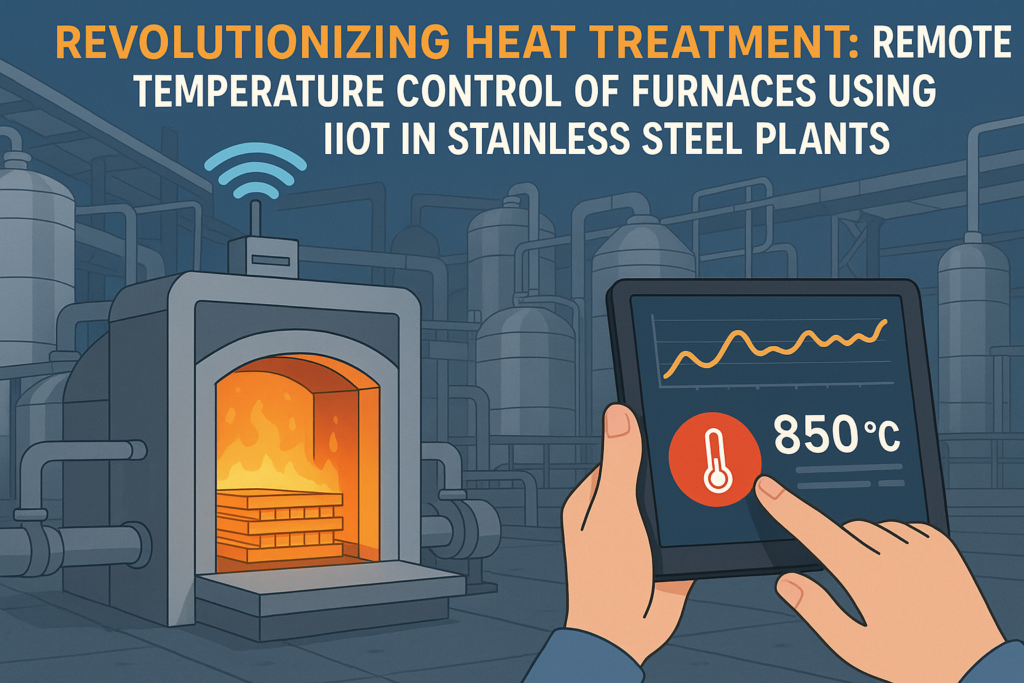

In the high-stakes world of stainless steel production, precision is everything—especially when it comes to heat treatment. This crucial process determines the mechanical properties, durability, and overall quality of stainless steel products. Traditionally, managing furnace temperature has required on-site monitoring and manual adjustments, a method prone to human error and inefficiency.

But now, the Industrial Internet of Things (IIoT) is changing the game.

The Challenge of Conventional Heat Treatment

Heat treatment in stainless steel plants involves complex thermal cycles that must be meticulously managed. Temperature deviations, even by a small margin, can lead to:

- Metallurgical inconsistencies

- Increased energy consumption

- Unplanned downtime

- Higher rejection rates

Moreover, in large-scale operations, monitoring and controlling multiple furnaces across various plant locations can be both labor-intensive and logistically challenging.

Enter IIoT: A Paradigm Shift

The Industrial Internet of Things (IIoT) brings real-time data acquisition, remote monitoring, and smart automation to the shop floor. With sensors embedded in furnaces and connected via secure networks, plant operators can now monitor, analyze, and control temperature parameters from anywhere—whether it’s across the control room or halfway across the globe.

Key Features of IIoT-Enabled Furnace Control

- Real-Time Monitoring

Temperature sensors feed continuous data into a centralized system, offering live insights into each furnace’s status. - Remote Control

Operators can adjust furnace settings via mobile apps or web dashboards, reducing the need for manual intervention and minimizing human error. - Predictive Maintenance

Analytics tools detect anomalies in temperature behavior, helping prevent equipment failure before it happens. - Energy Optimization

With precise control over heat cycles, energy usage can be optimized, reducing costs and carbon footprint. - Data Logging & Compliance

Automatically stored temperature logs ensure easy traceability and support compliance with stringent industry regulations.

Real-World Benefits for Stainless Steel Plants

Adopting IIoT in heat treatment isn’t just about embracing new tech—it’s about driving measurable results:

- 🔧 Reduced Downtime: Immediate alerts and remote troubleshooting minimize furnace outages.

- 🌱 Lower Energy Bills: Optimized heat cycles lead to significant energy savings.

- 🛡️ Improved Quality Control: Uniform heating ensures consistent metallurgical properties.

- 🧠 Smarter Operations: Data-driven decisions enhance productivity and strategic planning.

Looking Ahead: A Smarter, Safer Future

As stainless steel manufacturers aim for higher efficiency, better quality, and sustainable operations, IIoT-enabled furnace control emerges as a vital innovation. It transforms the age-old process of heat treatment into a smart, adaptive, and future-ready operation.

From the furnace floor to the cloud, the integration of IIoT technologies in stainless steel plants is redefining how heat treatment is managed—remotely, intelligently, and efficiently.

Leave a Reply