Controlling temperature precisely in a heat treatment furnace is critical to ensuring quality and safety in industrial metalworking processes. Whether you’re performing hardening, annealing, or tempering, maintaining the correct temperature and monitoring gas usage is essential.

In this post, we’ll explore a temperature controller system designed using a controller (like Arduino or PLC), a C# application, an 8-segment LED display, and a daily PNG gas consumption report. This setup helps automate the heating process, visualize real-time data, and optimize gas usage.

🧩 System Overview

The system is made up of four main components:

1. The Controller (PLC)

This is the brain at the hardware level. It reads temperature from a sensor (typically a thermocouple or RTD) placed inside the furnace. Based on the desired temperature setpoint, the controller decides when to turn the burner or heater ON or OFF. It communicates with the C# software using serial communication (e.g., through a USB COM port).

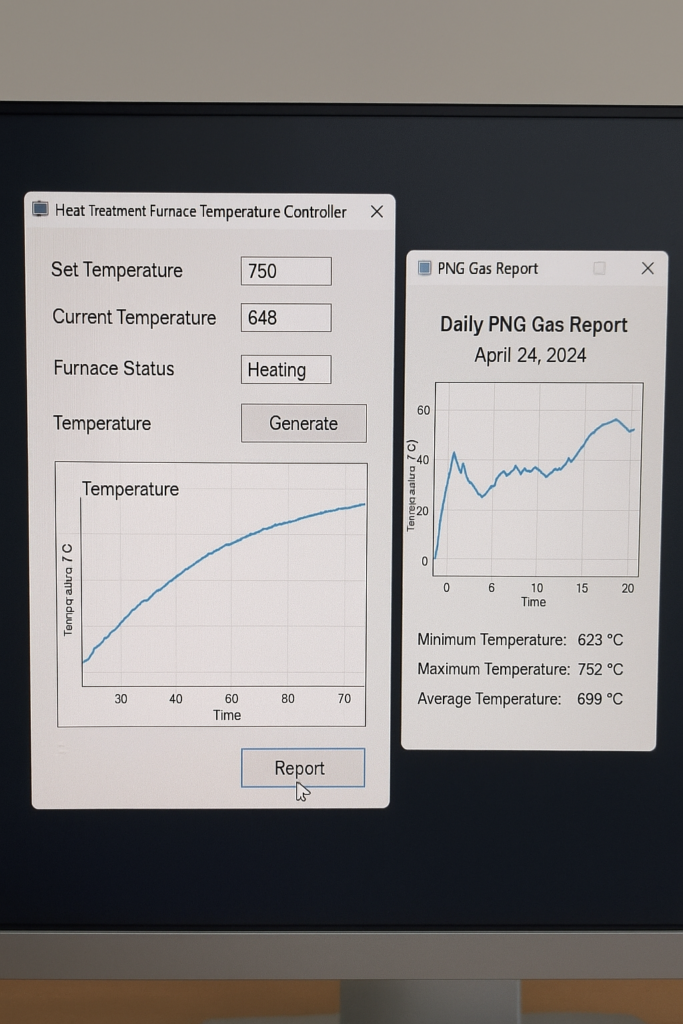

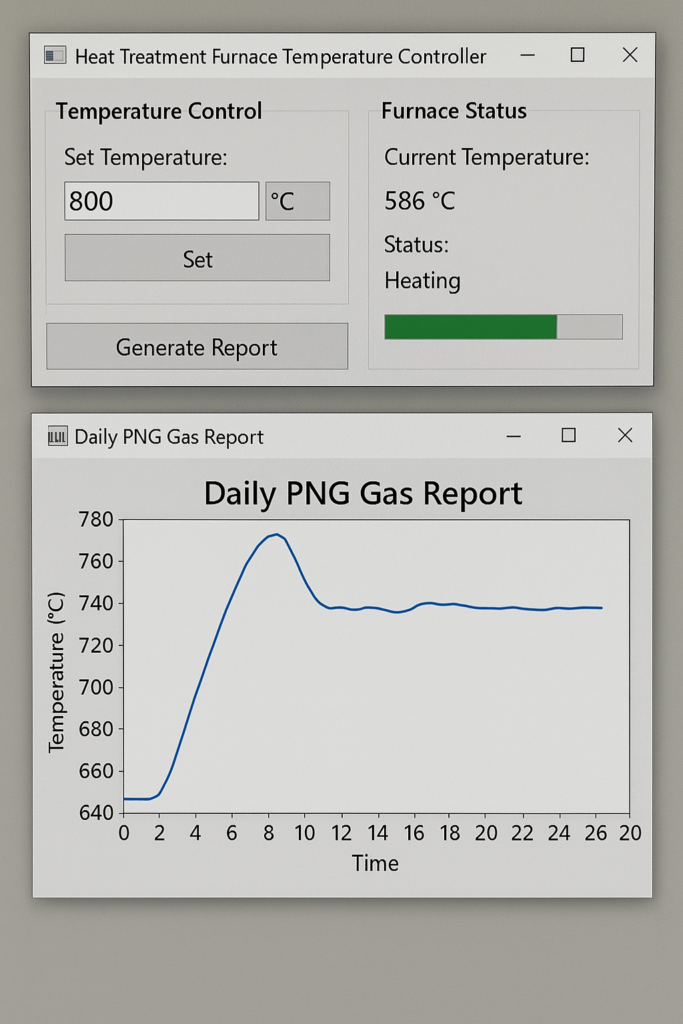

2. C# Desktop Application

The C# application serves as the interface and logic processor. It listens for temperature readings from the controller and displays them in real time. It also handles decision-making logic — for instance, whether the furnace should be heating or idling — based on a predefined temperature threshold and range. Additionally, this application records operational time to calculate gas consumption.

3. 8-Segment LED Display

This display visually shows the current temperature inside the furnace. Each digit is displayed clearly for quick reading by machine operators. The display is updated in real time using data received from the C# app or directly from the controller, depending on design preference.

4. Daily PNG Gas Consumption Report

To manage costs and monitor efficiency, the system keeps track of how long the furnace operates with the burner turned on. Using this runtime and a known gas flow rate, the application estimates how much PNG gas has been consumed. At the end of each day, a detailed report is generated. This report includes the date, total burner ON time, and the estimated gas used in cubic meters.

🛠️ How the System Works

🔄 Real-Time Temperature Monitoring

The temperature sensor sends readings to the controller continuously. The controller sends these readings to the C# application at regular intervals. This ensures that operators are always seeing the most current temperature on the display.

🎛️ Automatic Temperature Regulation

When the temperature falls below the desired level, the system activates the heating element or gas burner. Once the desired temperature is reached or exceeded, the system turns it off. A hysteresis range is used to prevent rapid ON/OFF switching, which helps in stabilizing temperature and improving the lifespan of hardware components.

📟 Display Integration

The 8-segment LED display shows the current temperature to operators on the shop floor. This is helpful for real-time monitoring without needing to look at a computer screen.

📊 Gas Usage Calculation

The time during which the burner is active is tracked throughout the day. By multiplying this ON time with a fixed gas flow rate (specific to the burner), the system estimates the PNG gas consumption. This information is logged and compiled into a daily report, which can be saved in CSV, Excel, or PDF format for analysis and record-keeping.

✅ Benefits of This System

- Precision Control: Maintains temperature with tight tolerances, reducing the risk of defective parts.

- Cost Monitoring: Tracks gas consumption to help reduce fuel costs and improve energy efficiency.

- Automation: Minimizes manual intervention by automatically handling heating logic.

- Visual Feedback: Clear and constant display of furnace temperature improves operational transparency.

- Documentation: Daily reporting provides traceability and accountability, especially for quality audits.

🚀 Possible Enhancements

- Add a PID controller for more advanced and stable temperature regulation.

- Integrate alarm systems for over-temperature conditions.

- Upload data to a cloud platform for remote monitoring and analytics.

- Support real-time graphing of temperature trends and gas usage.

🔚 Conclusion

A temperature controller system built with C# and a microcontroller offers a powerful, flexible, and cost-effective solution for heat treatment operations. It improves control, safety, and efficiency while offering clear reporting for operational insights. Whether you’re managing a single furnace or scaling to multiple units, this system can be tailored to fit your industrial needs.

Leave a Reply