Industrial Automation with C# and Mitsubishi PLC. In today’s fast-paced industrial landscape, automation is the key to improving efficiency, reducing human error, and driving overall productivity. With the rise of Industry 4.0, industries are increasingly turning to integrated automation solutions to streamline their operations. One of the most powerful combinations for industrial automation is the use of C# for developing applications that interface with Mitsubishi PLCs (Programmable Logic Controllers).

In this blog, we’ll explore how C# can be used to create robust industrial automation solutions, the benefits of Mitsubishi PLCs, and how Compiled Successfully Software Solution can help you achieve seamless automation in your manufacturing process.

Why Industrial Automation with C# and Mitsubishi PLC?

Industrial automation refers to using control systems, such as computers or robots, to perform tasks traditionally done by humans. This leads to several benefits, including:

Industrial Automation with C# and Mitsubishi PLC

- Increased Efficiency: Automation speeds up production cycles, allowing manufacturers to meet growing demand.

- Cost Reduction: Automated processes reduce the need for manual labor, thus lowering operational costs.

- Improved Safety: Automation minimizes human intervention in hazardous environments, reducing accidents.

- Real-Time Monitoring: Continuous monitoring of machinery ensures that any issues are detected and resolved promptly.

How C# Integrates with Mitsubishi PLC for Automation

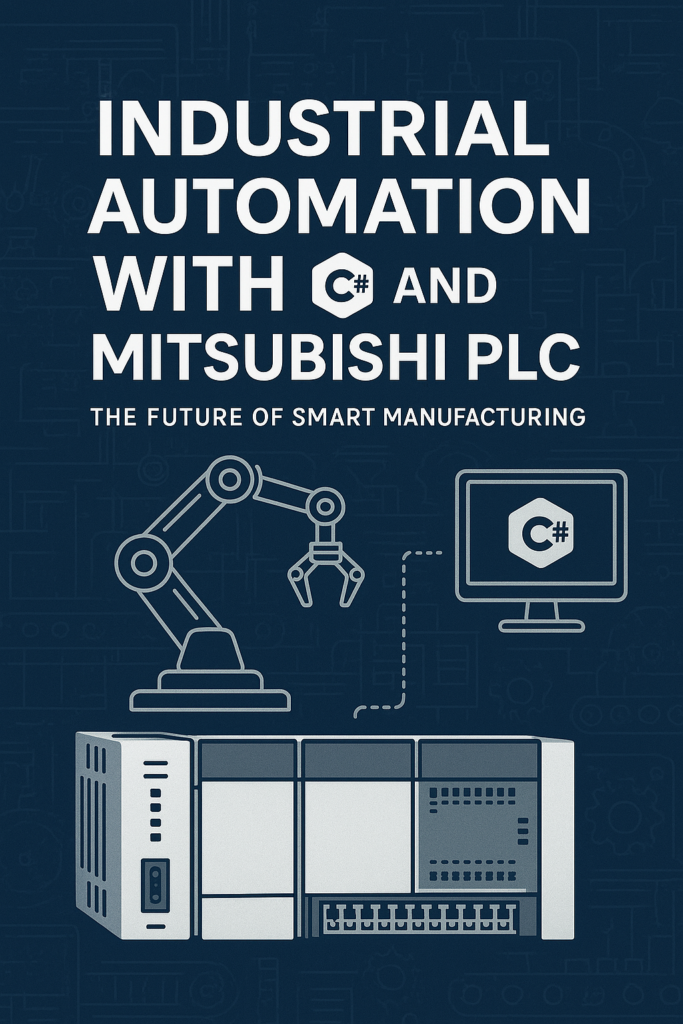

C# is a powerful, versatile programming language often used to develop Windows-based applications. When paired with Mitsubishi PLCs, C# can help design a wide range of automation solutions for industrial applications. Mitsubishi PLCs are renowned for their reliability and performance in demanding environments. Here’s how C# and Mitsubishi PLCs work together:

Industrial Automation with C# and Mitsubishi PLC

- Communication via Protocols:

C# can communicate with Mitsubishi PLCs through standard protocols like Ethernet, Modbus TCP, or even proprietary Mitsubishi protocols such as MC Protocol. By integrating these protocols into your C# application, you can easily read and write data from and to the PLC. - Real-Time Data Monitoring:

C# allows you to develop applications that provide real-time data from your Mitsubishi PLCs. Whether you’re monitoring production lines, machinery performance, or safety parameters, C# helps in visualizing and logging data efficiently. - Remote Control and Monitoring:

By using C# in combination with Mitsubishi PLCs, you can design remote monitoring and control systems. Operators can control machinery and troubleshoot systems from a central control room or even remotely via mobile apps. - Custom Dashboards for Visualization:

One of the key advantages of C# is the ability to design custom user interfaces. You can create dashboards that allow operators to monitor PLC data, generate reports, and visualize performance metrics in real-time. - Data Logging and Analysis:

With C#, you can implement data logging features to record information from the PLC for future analysis. By storing data in databases, you can run performance analysis and predictive maintenance algorithms to ensure machinery longevity.

Benefits of Mitsubishi PLCs in Industrial Automation

Mitsubishi Electric is a global leader in automation, and their PLCs are widely recognized for:

- High Reliability: Mitsubishi PLCs are known for their robust design and long-lasting performance in tough industrial environments.

- Scalability: Whether you’re dealing with small-scale operations or large industrial plants, Mitsubishi PLCs offer scalability to meet your needs.

- Ease of Integration: Mitsubishi PLCs are designed for easy integration with various communication protocols, including Ethernet, making it easy to link them with C# applications.

- Advanced Features: Mitsubishi PLCs offer advanced features like motion control, safety protocols, and IoT integration, which makes them ideal for smart factory solutions.

Why Choose Compiled Successfully Software Solution?

At Compiled Successfully Software Solution, we specialize in providing high-quality industrial automation solutions. Our team has extensive experience in developing software that seamlessly integrates with Mitsubishi PLCs, ensuring smooth communication and efficient control of your manufacturing processes.

Whether you’re looking to automate a single machine or an entire production line, we tailor our solutions to meet your unique needs. Our services include:

- Custom C# Software Development for Mitsubishi PLCs

- Integration of Industrial Control Systems

- Real-Time Data Monitoring and Reporting

- Remote Control Solutions for Industrial Machinery

- Predictive Maintenance and Data Analysis

Contact Us Today!

If you’re ready to take your industrial operations to the next level with Mitsubishi PLCs and C#-based solutions, Compiled Successfully Software Solution is here to help. We provide end-to-end automation services to help you achieve your manufacturing goals.

Company Name: Compiled Successfully Software Solution

Website: https://www.compiledsuccessfully.in/

Contact Details: +91 9220922267

Industrial Automation with C# and Mitsubishi PLC

Let’s work together to create the future of industrial automation!

Conclusion

Integrating Mitsubishi PLCs with C# offers a powerful solution for industrial automation, enabling manufacturers to improve efficiency, reduce downtime, and drive smarter operations. With the expertise of Compiled Successfully Software Solution, you can leverage the power of automation to stay ahead in an increasingly competitive market.

Leave a Reply