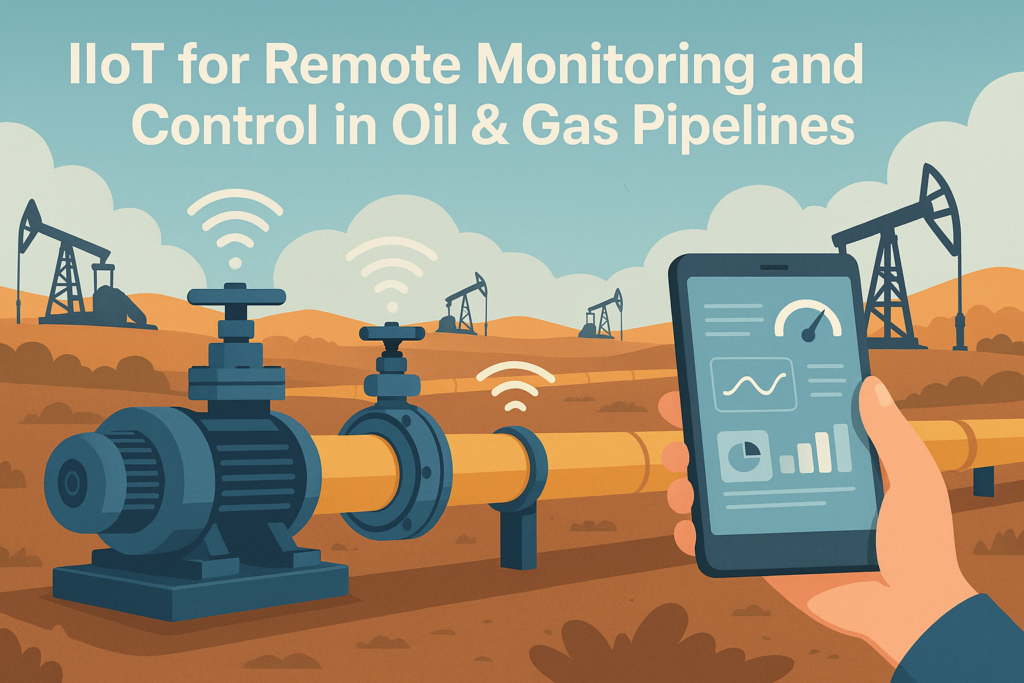

The Oil & Gas industry operates across vast, remote, and often hazardous terrains, making real-time monitoring and control of pipelines both a challenge and a necessity. Traditional methods, relying on manual inspections and SCADA systems, are now being transformed by the Industrial Internet of Things (IIoT).

IIoT enables the integration of smart sensors, edge devices, and cloud-based platforms to provide real-time data on pressure, flow rate, temperature, leakage, and equipment health. These data points are continuously analyzed, allowing operators to make swift, informed decisions from anywhere in the world. With IIoT, pipeline operators can detect anomalies such as pressure drops or unusual temperature variations that may indicate a leak or impending failure.

Remote control capabilities also enable operators to shut down valves, reroute flow, or activate emergency protocols instantly. This significantly reduces response time, mitigates environmental damage, and saves millions in potential losses.

IIoT-powered solutions are also equipped with predictive analytics, identifying potential failures before they happen. This shift from reactive to proactive maintenance improves asset lifespan, minimizes downtime, and enhances overall operational efficiency.

Automating Hazardous Environments: How IIoT Enhances Worker Safety in Oil & Gas

Safety is a top priority in the Oil & Gas sector, where workers often face harsh and high-risk conditions, including exposure to toxic gases, high pressures, and extreme temperatures. IIoT plays a pivotal role in mitigating these risks by automating tasks and enabling real-time environmental monitoring.

Smart wearables and gas detection sensors can continuously monitor worker vitals and ambient air quality. If hazardous conditions are detected, alerts are instantly sent to central control rooms and emergency response teams. This allows for immediate action, such as evacuation or containment.

Robotic systems and drones, powered by IIoT connectivity, can be deployed for inspections and maintenance in dangerous zones, eliminating the need for human entry. This reduces the risk of accidents and enhances compliance with safety regulations.

Furthermore, IIoT enables predictive safety analysis by collecting and analyzing historical incident data. Companies can identify patterns and implement targeted safety training or process improvements accordingly.

By transforming how information is gathered and responded to, IIoT empowers oil and gas companies to maintain high safety standards, reduce accidents, and ensure the wellbeing of their workforce even in the most hazardous environments.

🔄 Adaptive Control of Heat Cycles

By continuously collecting and analyzing real-time data, IIoT systems can dynamically adjust temperature ramps, hold times, and cooling rates based on material type, part geometry, and previous batch results. This kind of closed-loop control reduces variability and ensures repeatable quality.

🧪 Inline Quality Assurance

IIoT enables inline measurement and verification of critical properties such as hardness, microstructure, and case depth without needing to wait for lab results. Using NDT sensors and smart analytics, manufacturers can catch deviations earlier in the process.

🕸 Digital Twin Technology

A digital twin—a virtual replica of the heat treatment process—allows engineers to simulate, monitor, and optimize operations in a risk-free environment. Using real-time IIoT data, the digital twin stays in sync with the physical process, offering deeper insights into stress profiles, distortion risks, and performance predictions.

🌍 Remote Monitoring & Control

Whether you’re running multiple plants or offsite facilities, IIoT platforms offer remote access to equipment dashboards and KPIs. Engineers can review furnace health, production trends, or even start/stop cycles securely from anywhere in the world.

The IIoT Tech Stack: Behind the Scenes

Building an IIoT-enabled heat treatment operation involves multiple layers of technology working in harmony. Here’s a quick look at the stack:

- Sensors & Edge Devices: Thermocouples, pressure transducers, gas analyzers, and PLCs that capture machine-level data.

- Edge Computing Gateways: Devices that preprocess data and provide local logic control to reduce latency and bandwidth usage.

- Connectivity Layer: Wired (Ethernet, Modbus) or wireless (Wi-Fi, LoRaWAN) protocols that transmit data to the cloud.

- Cloud Platform: Centralized hubs that store, process, and analyze data with advanced algorithms and machine learning models.

- Applications Layer: Dashboards, alerting tools, mobile apps, and integration with MES/ERP systems for user interaction.

This layered architecture ensures scalability, flexibility, and security across the entire operation.

Starting the IIoT Journey in Heat Treatment

Not sure where to begin? Here are some practical steps to move toward smart heat treatment:

- Start Small: Identify one furnace or process line as a pilot project. Choose KPIs you want to track—like uptime, cycle accuracy, or energy usage.

- Assess Your Assets: Audit existing equipment for sensor readiness and connectivity. Retrofit older machines with modern sensors or PLCs if needed.

- Partner with Experts: Work with IIoT solution providers who understand both the technical and metallurgical sides of heat treatment.

- Train Your Team: Upskill operators, engineers, and quality staff to use and interpret real-time data.

- Scale Strategically: Once you prove ROI in one area, scale the system across the plant—and eventually, the enterprise.

A More Sustainable Steel Future

Smart heat treatment doesn’t just boost productivity—it contributes to sustainability goals. By improving energy efficiency, reducing rework, and minimizing scrap, IIoT helps lower the carbon footprint of steel production. As regulations tighten and green manufacturing becomes the standard, adopting IIoT will be essential not just for profits, but for the planet.

Final Thoughts

The fusion of Industrial IoT and heat treatment is more than just a technological upgrade—it’s a strategic evolution. Steel manufacturers who embrace this transformation will not only produce better products but also unlock agility, transparency, and competitiveness in a fast-changing world.

Heat treatment may have centuries of history behind it—but with IIoT, it also has a smarter, more connected future ahead.

Leave a Reply